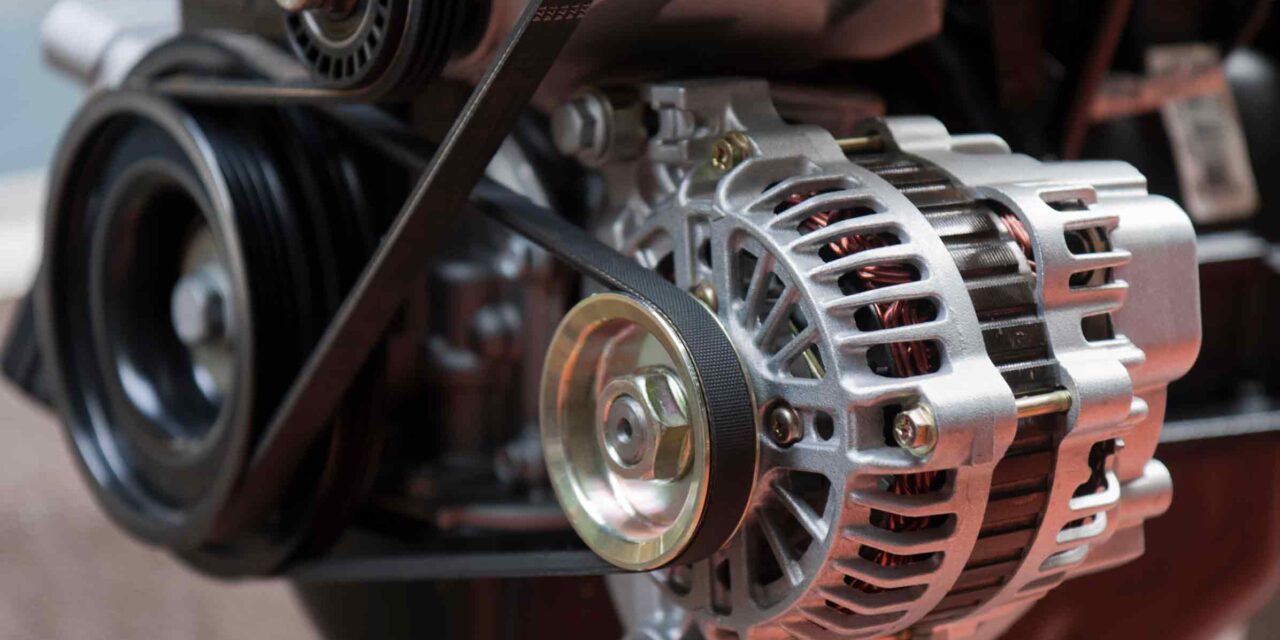

In the vast world of automotive components, the alternator stands out as a critical part that ensures your vehicle’s electrical systems function seamlessly. But its environmental impact is often overlooked, both during production and at the end of its lifecycle.

Materials and Production:

Raw Materials:

Alternators are made up of several metals, primarily copper and aluminum, with traces of silver, palladium, and other precious metals. Extracting these metals involves mining, which can degrade landscapes, produce waste materials, and pollute water resources.

Manufacturing Process:

The process of converting these raw metals into the intricate parts of an alternator demands energy primarily derived from fossil fuels. This energy-intensive process contributes to greenhouse gas emissions.

Transportation:

Distributing alternators to markets worldwide also has an environmental footprint. Transportation, especially when done via air or road, consumes fossil fuels, leading to further carbon emissions.

Lifespan, Waste, and Recycling

Durability:

High-quality alternators can serve effectively for over 100,000 miles, reducing the frequency of replacements and thereby minimizing waste. Conversely, lower-quality alternators might fail sooner, necessitating more frequent replacements and producing more waste.

End of Life:

Failed alternators, if not correctly disposed of, contribute to electronic waste, which can leach harmful chemicals into the ground, affecting soil and water sources.

Recycling:

The good news is that alternators are largely recyclable. Their metal components can be melted down and repurposed, reducing the need for new raw materials and mitigating the environmental consequences of mining.

Towards a Greener Future

Eco-friendly Designs:

Manufacturers are researching ways to extend the life of alternators, thereby reducing waste. There’s also ongoing research into using more sustainable materials in production.

Consumer Awareness:

As consumers, opting for quality parts, ensuring proper disposal of old alternators, and supporting brands that prioritize eco-friendly practices can make a significant difference.

Conclusion:

While the alternator’s environmental impact may seem insignificant when viewed in isolation, it becomes essential in the grand scheme of automotive components and the sheer volume of vehicles worldwide. Both manufacturers and consumers have roles to play in making the journey of the alternator more environmentally friendly.